Asbestos Containing Brake Pads – A Mechanics Concern

Asbestos was widely used in the past as a component of brake pads and other automotive friction materials due to its heat resistance and durability. However, awareness of the health risks associated with asbestos exposure led to a decline in its use in the automotive industry. Today, the use of asbestos in automobile brakes has significantly decreased, but it's important to understand the current situation and the potential risks involved.

In many countries, including the United States, the use of asbestos in brake pads and linings has been phased out or heavily regulated. Regulatory agencies such as the Environmental Protection Agency (EPA) have set strict standards and guidelines to protect workers and the general public from asbestos exposure. Most automotive manufacturers and suppliers have transitioned to alternative materials that don’t contain asbestos.

Nonetheless, it’s essential to be aware that there are still certain countries where asbestos-containing brake pads may be manufactured and used. In some regions, particularly in developing countries, the regulation and enforcement of asbestos bans may be less stringent or inconsistent. As a result, there’s a possibility that imported brake pads or aftermarket products from these areas could contain asbestos.

To address these concerns, many countries have implemented regulations to control the import and sale of asbestos-containing products, including automobile brakes. However, it can be challenging to completely remove all asbestos-containing products from the market due to various factors such as supply chains, counterfeit products, and limited enforcement resources.

To ensure your safety, it’s important to stay up-to-date and make informed choices when it comes to maintaining your vehicle's brakes. Here are some measures you can take:

- Consult with professionals: When having your brakes serviced or repaired, consult with a reputable automotive repair shop or mechanic who can provide information about the brake pads and linings they use. They should be able to verify whether their products are asbestos-free.

- Purchase from trusted sources: If you plan to replace brake pads yourself or purchase them for a DIY repair, make sure to buy from reputable suppliers or manufacturers.

- Read labels and certifications: Check the packaging or product labels for information about the composition of the brake pads. Look for certifications or compliance with regulations such as the EPA's "NESHAP" (National Emission Standards for Hazardous Air Pollutants) standards or similar local regulations.

- Use personal protective equipment (PPE): If you’re doing brake work and are unsure about the presence of asbestos, it’s advisable to take precautions. Wear appropriate personal protective equipment, such as gloves and a mask, to minimize potential exposure to any dust or particles.

- Dispose of brake components properly: If you are replacing brake pads yourself, ensure that you dispose of the old pads properly. Contact your local waste management or recycling facilities to determine the best way to handle asbestos-containing materials according to local regulations.

If you own a commercial automotive shop where more than five brake or clutch jobs are performed per week, it’s required to comply with OSHA regulations. These regulations dictate the use of specific work practices or equivalent methods. The following are the approved work practices:

- Negative-Pressure Enclosure/HEPA Vacuum System Method: This method involves using a specialized box with clear plastic walls or windows. The box is tightly sealed around a brake or clutch assembly to create a negative pressure environment, preventing asbestos exposure. Additionally, a high-efficiency particulate air (HEPA) vacuum system is employed to capture and contain any asbestos particles that may be released.

- Low Pressure/Wet Cleaning Method: This method utilizes specially designed low-pressure spray equipment. The brake assembly is wetted down using this equipment, and a special basin is used to collect the runoff. By wetting down the brake assembly, the generation of airborne brake dust is minimized, preventing its dispersion in the work area.

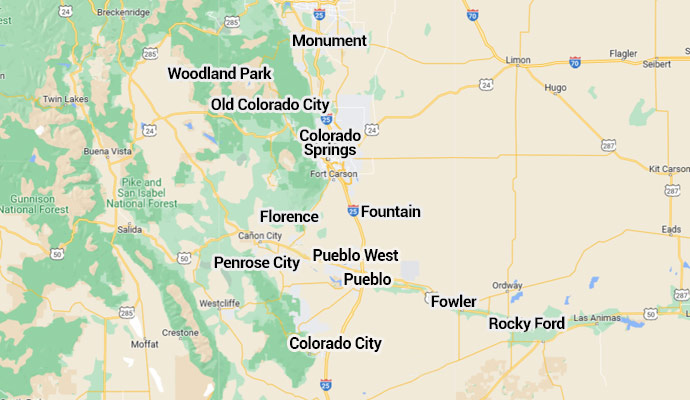

Moreover, if you’ve been in business for a while, asbestos fibers may contaminate your entire building. Having it tested for asbestos and professionally removed is vital. Cyclone Kleenup is a fully licensed, bonded, & certified company that can provide effective asbestos testing and removal services. Our IICRC-certified technicians carry state-of-the-art equipment and use cutting-edge technology to find, contain, and remove the threat of asbestos from your property in Pueblo, Penrose, Colorado Springs, Florence, and other cities that we serve within our Colorado service area. Call us NOW at 719-299-3887 to learn more or click here to remove asbestos from your property ASAP.