Nothing Beats Media Blasting for Clean Surfaces

Media blasting is a process that uses a high-pressure stream of abrasive particles to clean, strip, or etch surfaces. Media blasting is commonly used for a variety of applications, such as cleaning and restoring buildings, bridges, and other structures, as well as for removing paint, rust, and other coatings from surfaces. In Colorado, media blasting is regulated by the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA), which have established guidelines for the safe use of media blasting.

There are several types of media blasting, each with its own advantages and disadvantages. Some common types of media blasting include:

- Sandblasting: This is one of the most common types of media blasting. It uses sand as the abrasive material and is typically used to remove paint, rust, and other coatings from surfaces.

- Glass blasting: This method uses crushed glass as the abrasive material and is typically used to remove coatings like paint, rust, and others.

- Bead blasting: Small beads are used as the abrasive material and are typically used to remove paint, rust, and more.

- Soda blasting: Baking soda is the abrasive material utilized and is typically used to remove paint, rust, and other coatings from surfaces without causing damage to the underlying surface.

- Dry Ice Blasting: Employs low-abrasive media using CO2 (dry ice) pellets projected at a high velocity. It’s good for a wide variety of applications like mold cleaning, food processing, and in ethanol plants. This system is not as messy with less cleanup because the dry ice evaporates on impact.

Before media blasting begins, a safety plan must be developed and approved by OSHA. This plan should include safety measures for the workers, such as the use of personal protective equipment, and guidelines for the disposal of waste materials.

During the media blasting process, the surface to be cleaned or stripped is first prepared. This may include removing loose debris and masking off areas that should not be blasted. A nozzle is then used to direct the stream of abrasive particles at the surface, which removes the coating or surface material. After the media blasting is complete, the surface is cleaned and inspected to ensure that all of the coating or surface material has been removed. If necessary, a new coating or surface material can be applied.

It's important to note that media blasting can be a dangerous process and should only be carried out by professionals with the proper training, equipment, and experience. Media blasting can release hazardous particles into the air and can cause serious health problems if inhaled. Therefore, it's important to follow the safety guidelines established by OSHA and the EPA and to use the appropriate personal protective equipment.

In addition, Media blasting may also have an environmental impact, so companies should follow the regulations established by the EPA and state authorities regarding waste management and disposal of abrasive materials.

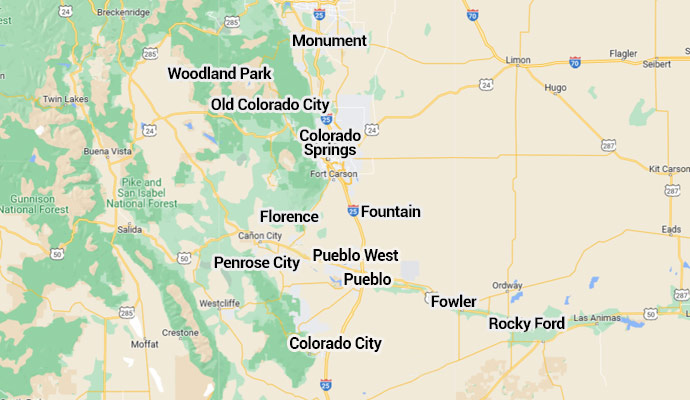

Cyclone Kleen Up has extensive experience selecting the appropriate media blasting solution for your unique application. Count on us for any job, big or small! Our media blasting services are available in Colorado Springs, Penrose ,Salida, Florence and other cities in our service area. . Call 719-299-3887 or click here to make a service appointment ASAP.